The two primary methods for producing di-esters used as plasticisers are: esterification (used by Grupa Azoty ZAK S.A. in the production of Oxoviflex™ (DEHT, DOTP)) and transesterification (used by other producers). Depending on the technology by which the plasticiser is obtained, its composition and properties may vary.

Production process

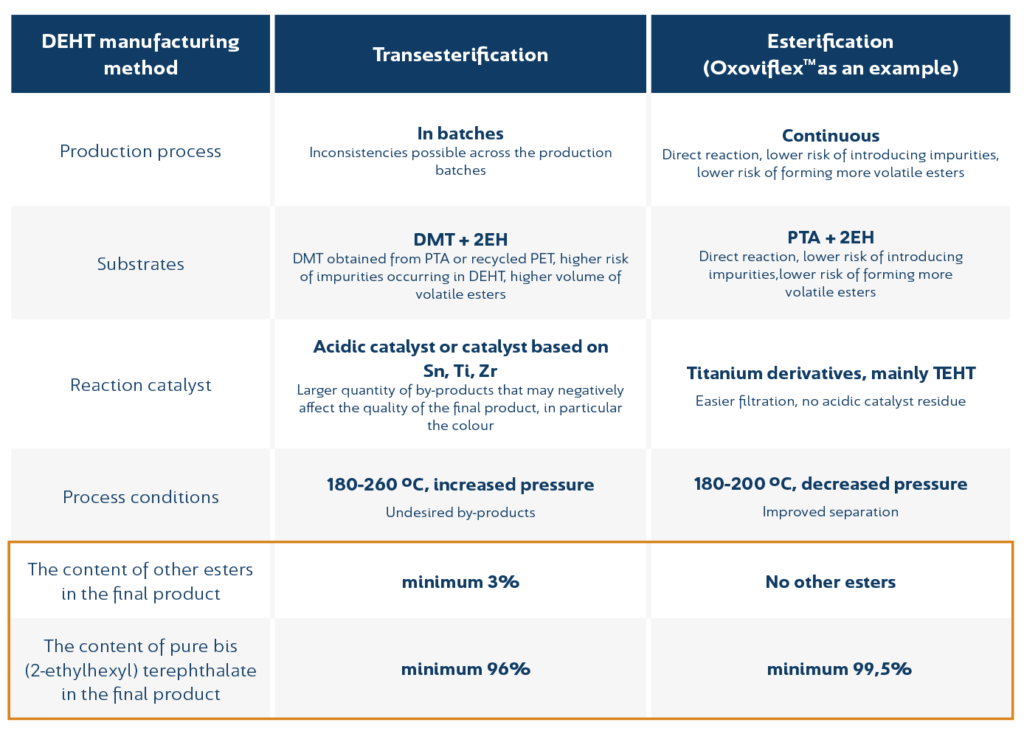

Oxoviflex™ is produced in a continuous process on a dedicated facility, based on the reaction of terephthalic acid with 2-ethylhexanol. This enables real-time process control and the maintenance of consistent product quality parameters. In the case of DEHT formed by the transesterification process, the batch method is predominant, which can result in batch-to-batch variation of the product, especially if it is carried out on one facility interchangeably with the production of other plasticisers.

Raw materials

Another feature that sets the two processes apart is the raw material used. The esterification process is carried out directly through the reaction of terephthalic acid with 2-ethylhexanol (PTA + 2EH), in which water is the by-product. Conducting the process with only PTA and 2EH eliminates the risk of mixed-methyl-octyl esters.

In the case of transesterification, alongside 2-ethylhexanol, dimethylterephthalate (DMT) is the primary raw material and methanol is the by-product. DMT can be obtained from terephthalic acid (PTA) or by alcoholysis of polyethylene terephthalate with methanol (recycling of PET products). The necessity of producing DMT from PTA or obtaining it from recycled PET can lead to the impurities being introduced with it.

Reaction catalyst

For Oxoviflex™, the esterification reaction is catalysed by titanium compounds, mainly TEHT. The catalyst itself is an amphoteric catalyst that decomposes to TiO2 when exposed to water, which facilitates its separation from the product by filtration, and reduces the amount of agent required to neutralise the raw ester. Organometallic catalysts are more selective, with fewer by-products formed when they are used and much easier to separate by precipitation.

The transesterification reaction is catalysed by an acid catalyst (sulphuric acid, methanesulfonic acid, p-Toluenesulfonic acid) or one based on tin, titanium or zirconium compounds. In the case of acid catalysts, larger quantities of by-products are produced, negatively impacting the quality of the final product, specifically its colour.

Process conditions

Oxoviflex™ is produced at 180-200°C, under reduced pressure. The process is carried out in terephthalic acid suspension in an excessive amount of 2-ethylhexanol. This allows better separation of unreacted terephthalic acid from the ester on adequate filters. Lowering the pressure at which the reaction is carried out reduces the temperature required for the process, which not only boosts the energy output of the process, but also results in fewer by-products being formed. The transesterification process requires higher pressure conditions and a higher temperature of 180-260°C, and is carried out in a homogeneous mixture of reactants, which leads to the formation of undesirable by-products.

Summary

All the above-mentioned discrepancies have a bearing on the quality of the product. Obtained by esterification, Oxoviflex™ is chemically purer, as it is produced under conditions that are less conducive to the formation of by-products, whereas in DEHT produced by transesterification there can be up to 3%. In its composition, Oxoviflex™ contains min. 99.5% of pure bis (2-ethylhexyl) terephthalate, while transesterified products contain 96%.

Through a selective esterification reaction involving terephthalic acid and 2-ethylhexanol, a high-purity product with excellent quality parameters is produced.

Oxoviflex™ is a safe product, free of acid catalyst residues, residual methanol and phthalates. In terms of metal content, it can be compared to plasticisers produced for medical purposes, meeting the highest quality criteria including the European Pharmacopoeia guidelines.

One of the distinctive features of DEHT produced by esterification is the qualitative stability of subsequent batches of the product in terms of transparency (colour). This may be particularly important in the production of coloured components, as the risk of colour variations in the product is minimised, so the need to adjust the quantity of dosed colouring agents in production mixes is reduced. This is particularly true for all bright colours, (from white through beige to light brown), where a change in the transparency of the plasticiser substantially impacts the overall perception of the colour of the final product.

Bibliography:

- US 7361779 B1 “Low-melting mixtures of di-n-butyl and diisobutyl terephthalate”

- US 7964658 B2 “Dialkyl terephthalates and their use“

- WO 2010/071717 “Polymer compositions comprising terephthalates”

- PL 216179 B1 “The method of obtaining dioctyl terephthalate”

- US 20150307435 A1 “Esterification Process”

Author:

Szymon Ustrzycki

An expert paper, author: Szymon Ustrzycki

Specialist Product Engineer / Oxoplast / Grupa Azoty ZAK S.A.