The 30th anniversary of the OXO alcohol system commissioning at Grupa Azoty ZAK S.A. is a unique event, not only for the plant but predominantly for the people who are the foundation for the company value. They opened a special phase in the history of Grupa Azoty Zakłady Azotowe Kędzierzyn, which was setting up the OXO Segment. It is a perfect occasion to reminisce. We would like to recount the history of the man inherently connected with the factory, Mr Łukasz Kaleciński.

I first worked with the OXO system in April 1982 together with the entire team then selected to work on its construction and erection. Yet my own role in the system still constructed entailed something completely different. I had been employed to prepare all the system units for commissioning after the construction ended and then to operate the system and handle production. Thus, I was not involved in the construction directly but had to monitor it scrupulously, spot any design errors, though occurring rarely, and respond instantly. In addition, I had to track the progress made by construction and erection workers so that they would not take shortcuts. All that to avoid any problems which could happen in the future. Moreover, I prepared myself to know the new technology to be able to follow the process requirements following system commissioning. I remember very clearly my first serious and responsible assignment. In June 1982, I was obliged to collect, carry safely and store properly the costly rhodium catalyst. It was the key spice in the entire future process. The catalyst was the product of the then state-of-the-art technology. It was used for the first time in the world by Americans in their plant in Puerto Rico. That catalyst was extremely expensive for its main component rhodium was more expensive than platinum. A UK-based company, Johnson Massey supplied the catalyst. My duty was to collect it from the Okęcie Airport and carry it safely to Zakłady Azotowe. Note that martial law had been already declared and very rigorous restrictions applied in all of Poland which concerned road transport too. The catalyst shipment consisting of five big cases was regarded as valuable and precious and to transport it according to the applicable regulations of martial law a special convoy was appointed. The licensor imposed excessive conditions for how the catalyst should be stored. Therefore, all the requirements had to be met and I took a great care to accomplish that.

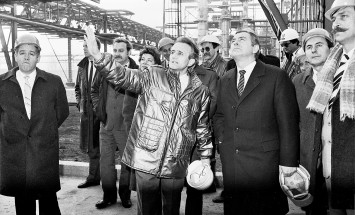

I must say that the entire system construction and commissioning process was a long series of challenges which we had to face. Another of such challenges was the selection of the competent staff. That was one of my duties as well. Since the system was state of the art, I could not accept people at random. I knew the plant and the staff arrangement quite well. Thus, to prepare the future OXO system team, I used to move around the plant, talk to the employees and recruit them. Then, it was very helpful to know the plant employees. It was not an easy task. At that time, the factory saw the staff drain because many of its employees left for West Germany or other companies which offered business trips to perform export contracts. When hiring the employees, I fell into disfavour with managers. Jokingly, they used to call me the “sadistic dentist” because my actions were like pulling out a healthy tooth without anaesthesia. Then, the new staff underwent a series of intensive training programmes. All the engineers went to the US to take training at Union Carbide in Texas and at the institute in West Virginia. That is where they researched our process. On return, we trained the employees. After the construction ended, we started commissioning. Much to our surprise and to licensors’ surprise, the entire commissioning process went through painless and the product was of high quality. That was the result of the very meticulous preparation for commissioning, maintaining high process requirements and adhering scrupulously to the quality standards of raw materials. I remember the surprise of the entire sector when in December 1986, having previously been the importer of octanol, we became the exporter. We were able to manufacture such an amount of octanol that was sufficient to satisfy the company’s needs to manufacture dioctyl phthalate and then-Director Chmielewski provided over 500 tons of octanol for export. We were suspected of re-export but the truth was we had already had our own octanol and its amounts were growing even faster.

During the trial run of the system, it turned out that all the parameters were correct and we were looked at with a positive surprise. Success? Unquestionably. People? Of course. I remember our boss Engineer Szopa most. In my opinion, he was the best boss I have ever worked with in my industrial career. Great man. Engineer Szopa integrated our entire team. Every day, he used to chair meetings where we discussed all the affairs connected with the systems and then we took decisions. Interestingly enough, we did not make the arrangements individually but jointly. Engineer Szopa had one very interesting quality. When you carried out a discussion with him and had a different opinion, Mr Szopa could bring anybody round. Anyhow, his motto was, “A convinced man leaves the discussion as your friend and the defeated man leaves it as your enemy”. He had never tried to beat anybody in a discussion; he always tried to convince you and this is how I still remember Engineer Szopa today.

These are the people in Grupa Azoty ZAK who allowed us to be confident about our future and to be considering further growth, set ambitious goals and continuously pursue them. All the energy that we have put to do the good job bore fruit in the form of trust and prestige on international markets. Every person working here, every day of our history and every achievement were and are crucial for the here and now of Grupa Azoty ZAK S.A. For us, it is an individual that is most important at every anniversary celebration. The continuity of generations creates the body of experience and has provided the employees with the skills which allow them to develop the modern OXO Segment.

About the company

Grupa Azoty Zakłady Azotowe Kędzierzyn Spółka Akcyjna is one of the largest chemical producers in Poland, being a member of Grupa Azoty. The company has a long tradition and respects human and social values. Its business operation is based on the two main pillars: nitrogen fertilisers as well as OXO alcohols and plasticisers. The company is the producer of e.g. the first Polish non-phthalate plasticiser called Oxoviflex®, a product awarded by the Polish Agency for Entrepreneurship Development with the prestigious title of the Polish Product of the Future. The mission of the company is to provide the highest quality products to customers. The offered range is intended for the following sectors: agriculture, construction, chemical processing and plastics industry. The company has its own co-generation plant, loading port and provides specialised laboratory services. It is also the owner and the main sponsor of the extra league volleyball team – ZAKSA Kędzierzyn-Koźle.